-

-

Steel Quality

-

"The good cutting edge" is from "The good quality steel"

ARS, together with the steel manufactures, has been developing the most suitable quality steel for the ARS tools. It must clear ARS's own highest standard steel level after having cleared the JIS(Japan Industrial Standard).

-

-

-

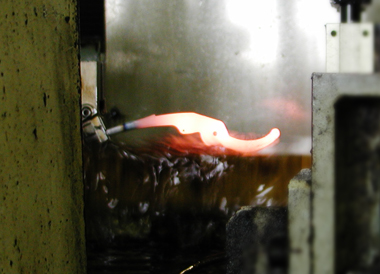

Thermal Treatment

-

"The Tenacity" and "The Hardness" is the key factor of cutting edges.

ARS, together with the furnace manufacture, has developed own system.

ARS has managed to convert the skill of experienced master technique into the numerical scale. This then be led to the automatic thermal treatment and thus to produce the high grade of thermal treated steel.

-

-

-

Grinding

-

In order to produce the reliable products, ARS has been doing from the research of the own production process to the development of its own machine on all the products.

By converting the master technique into the numerical scale, it enabled to produce the every small edge angle on saw tooth is applied on the mass production.

-

-

-

Design

- ARS new design features ergonomic, economic and durability.

-

HOME > Technology

Technology Policy

Basic Technology

-

Material

High-Carbon granular spheroid annealing Steel The steel for blades which is a chemical compound made up of iron and carbon, and more carbon makes harder. We select the steels carefully and use only steels with High-Carbon granular spheroid annealing. This is applied on all the items.

-

Thermal Treatment

Marquench Hardening (hot bath quenching) Commonly the hardening is know as hardened by heating up to the hardening point and then cooled it down in the water or in the oil. ARS apply the hardening system which has the control of the perfect temperatures for heating up and cooling down. This produces the extremely hard and yet tenacity steel which is suitable for ARS quality blades.

-

Impulse Hardened

The new impulse hardening method involves both heating and cooling within several thousandths of a second, using impact energy created by high frequency currents. This method has enabled ARS blades to embody the remarkable hardness of 900HV to 950HV on the Vickers scale, above any reading on the Rockwell C scale, and still retain their high elasticity. Impulse hardening will extend blade life by approximately three times in normal usage.

-

Hard-Chrome Plating

Hard-Chrome plating offers greater hardness, rust proofing, sharp looks and superior durability. The smooth surface prevents resin from sticking to and accumulating on the blades.

-

Fluorocarbon Resinating

It smoothes the surface sliding and enable to produce extra cutting performance. The coating prevents from resin and stain. Applied: 185-1.5, LP series, K-950Z

-

Chemical-Nickele Plating

The coating prevents from resin, stain and rust. Applied: TL series,UV/CT series,CAM-18LN &24LN, CB/CBR series, K-800, K-900Z.

-

Super High Speed Steel

Super High Speed Steel has developed in recent years with totally different concept of making steel which is extremely hard compare to the ordinal ones. ARS has quickly taken this material up and managed to produce the Aramid Cutting Scissors, ARSuper 526-H.

-

Spare Blade System

Convenient and economical system has been applied on all the saws & Long Reach Pruners, CB/CBR series,V series, SE series, K-1000, K-1000L, K-1100, LP-series and 526.

Technology of the Scissors/Shears

-

Soft Grip

From the Ergonomic point of view, the grips of the scissors and shears are designed to reduce the unnecessary burden. However, when it is necessary to cut hard material it will yet produce the fatigue free even holding with full power. Applied: V series, CB series, CBR series, 120DX series, 120S series, craft scissors series, 300 fruit pruner series and FL series.

-

Cut and Hold System

Adoption of the original Holding Spring Function (120DX-T Patent being in process), it is able to cut and hold the fruits and flowers. Applied: 120DX-T, 120EU-R, 150 series, 160 series.

-

The tilting System

The cutting head of telescopic long reach pruners are able to be tilted for 30 degree to each side. This enables to fix in the position of choice in accordance with the position of the cutting objects. Applied: Long Reach Pruner ZR series.

-

Dial Centre Nut System

By making the slight adjustment of the tightness with the centre fulcrum dial nut, it enables to cut till the tip of the blade effectively without slipping the cutting objects out from the edge. Applied: 526 series, K-800, K-900Z and K-950Z

-

Non Symmetry Design

Non symmetry designed grips produce the ergonomic fitting into the users' hand which has the characteristics of better handling and more cutting force without fatigue in long time usage. Applied: V series, CB series, CBR series and 526 series.

-

Soft Rubber Shock Absorbing Bumper

It is applied to reduce the kick back impact when cutting off the objects by absorbing with the cushioning system. Applied: K-1000, K-1000L, K-1100, LP series, All the Long Reach Pruners, All the Telescopic Long Reach Pruners, 185 series, 180L series, V series, 130 series, 140 series, 526 series and FL series.

Technology of the Saw

-

UV-CUT

With the application of special tooth (UV shaped tooth), it gives the opportunity of smooth cutting performance on wooden objects in horizontally, vertically or any angle. The special surface treatment offers greater hardness, rust/clog proof and superior durability.

-

ARS Tooth

Compare to the conventional saws, ARS saw has no off-set teeth. Instead, ARS apply "Taper Grinded Tooth" in which the saws are thinner on the back of saw and thicker at the teeth. This produce the systematically same function as off-set tooth of conventional saw. However, this new ARS tooth technology resulted on the clean cutting surface, as smooth as cream. Applied: Most of the saws

-

Tooth Grinding

Each tooth is grounded as sharply as mirror. This produce the excellence of the cutting performance without the clog. Applied: All the saws

-

Curvature Grinding Technology

It is designing to prevent the breakage of the saw, near the grip by becoming the fulcrum in the event of wrong usage. By applying the diagonal grinding line near the grip, it gives the tenacity against the side bending and gives the extra strength against the breakage.

-

Changeable Grip Angle

For the efficiency of smooth cutting, the saw fixing angle inside the grip is designed to be adjustable in two different stages. Applied: TL series.

-

Guiding Roller in Sheath

Roller is fixed at the entry of the plastic sheath which enables the smooth inserting and taking out without ruining neither the saw blades nor the sheath. Applied: TL series and CAM series UV/CT series.